Sub-slab vapor collection systems are important for mitigating volatile chemicals, methane gas, radon, and other contaminants from entering building structures.

What Are Vapor Collection Systems?

Vapor collection systems are placed underneath building foundations to efficiently collect and then discharge contaminated vapors up and above the roofline. These systems serve three main purposes:

- Dilute contaminant vapor concentrations that accumulate under a structure.

- Help equalize the pressure differentials between the sub-slab and the building through sub-slab air exchanges.

- Remove the ability for contaminated vapor to collect underneath the building by expelling it.

Advection and diffusion are the two main factors that drive the occurrence of vapor intrusion and increase your likelihood of needing a vapor collection system.

Active Vapor Collection Systems

Active vapor collection systems utilize mechanical means to collect sub-slab vapors and expel them above the structure in order to keep chemical vapors out of the structure. For existing structures, this is the most common form of vapor intrusion mitigation.

While active vapor collection mitigation is highly effective, it’s also often more expensive than passive vapor collection systems because continued operation and maintenance can be costly.

A sub-slab depressurization (SSD) active vapor collection system involves the use of a blower or electric fan. The installation of a suction pit or plenum in the sub-slab allows for contaminated vapors to rise to the surface and into the structure. The electric fan then forces out the chemical vapors and releases them outside of the structure.

SSD systems can also be coupled with a vapor intrusion barrier to create system efficiency and/or create additional redundancy in case the SSD becomes inactive or is not properly maintained.

Another form of active mitigation involves adjusting your building’s HVAC systems according to the pressure in your sub-slab. When positive pressure is introduced inside, it prevents chemical vapor from entering your building. This involves incredibly high energy costs than SSD. It’s worthwhile to note, however, that both of these active methods are more expensive and tumultuous than a passive vapor collection system.

Passive Vapor Collection Systems

Passive vapor mitigation systems (those without mechanical fans) are typically installed during the construction of a new building and are almost always coupled with a vapor intrusion barrier.

There are different methods for utilizing passive vapor collection systems. This approach can also be utilized on existing structures, though it is not as common. In order for the approach to be employed, the existing slab must be removed, or a new slab must be placed over the existing one.

An alternative approach is to design a passive system with the option to convert it to an active system if needed in the future. This approach affords building owners with maximum flexibility.

Selecting Your Next Vapor Collection System

Methods for vapor mitigation in new construction can be passive — think vapor barriers and natural venting systems — or they can be active via the use of fans to depressurize the sub-slab area. In the end, passive vapor systems are a more cost-effective approach, making them the most common and appealing method for new construction.

EPRO offers a low-profile vent material that greatly expedites the construction process by eliminating the need to dig vent trenches, backfill them with filter fabric, gravel and slotted pipe material. This also helps to alleviate strain on a construction budget, as common slotted pipe material often includes more costly PVS or ADS piping.

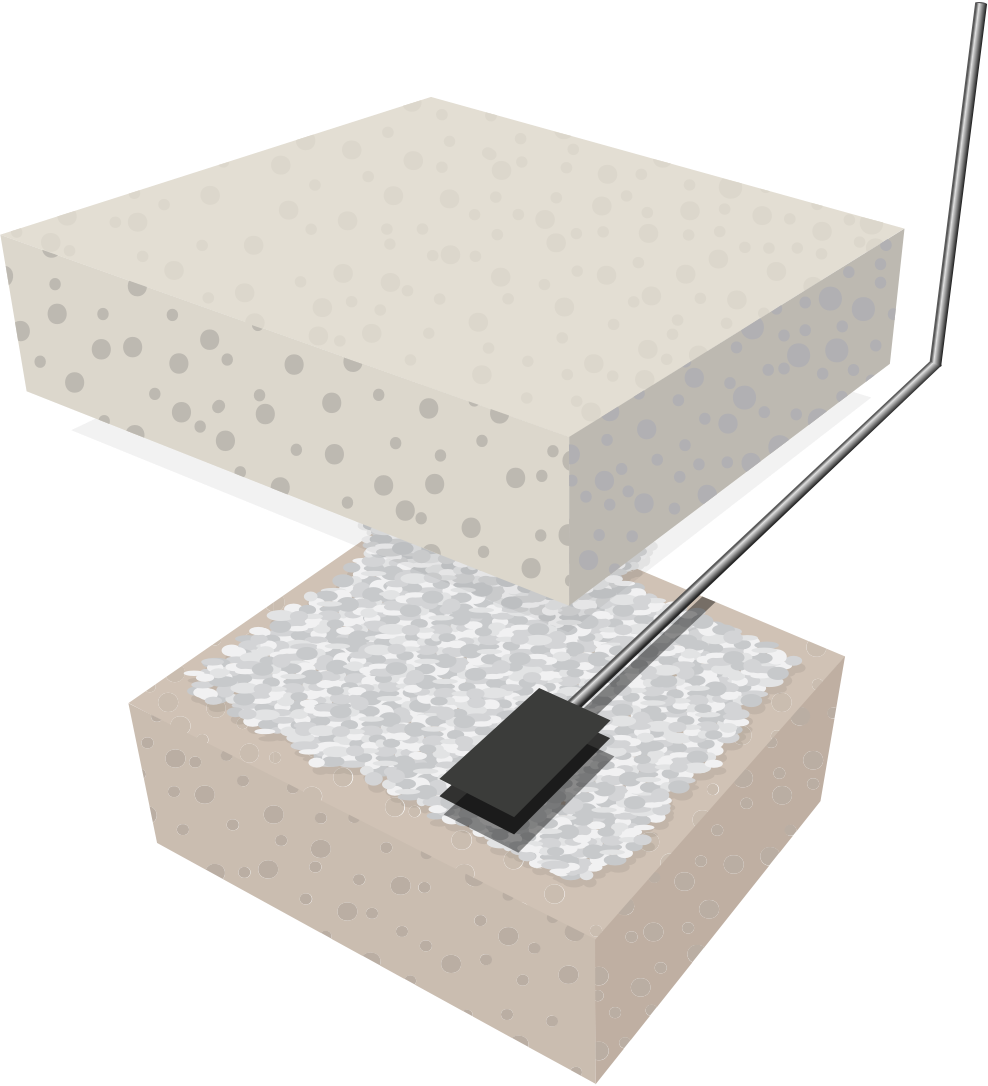

EPRO’s Vapor-Vent® vapor collection system is a composite, low-profile, pressure relief and collection system designed to mitigate the build-up of contaminated vapor and methane gas under an overlying structure. Vapor-Vent® can be combined with any of the vapor intrusion barrier options provided by EPRO.

It’s most commonly designed to operate as a passive collection system, but it can be designed to work as an active system when conditions require it.

It features a lightweight, 3D, highly flexible polypropylene core and a non-woven geotextile filter fabric. The filter fabric is bonded to the polypropylene core to prevent fine substrates, such as sand, from clogging the vent pipe.

Vapor-Vent® is a cost-effective alternative to traditional trenched PVC or ADS pipe systems. Simply place it directly below your barrier system, placed within permeable substrates, and it will drastically reduce vapor accumulation underneath the structure. Note: This system should avoid instances of continual submersion or being subjected to groundwater.

Want to learn more about vapor collection systems? Check out EPRO’s Venting Systems to find the solution that works best for your project. Or click here to start your no-obligation evaluation.