Planning a commercial construction project can be a daunting task. There are so many different considerations to plan for, often to tight deadlines and high expectations — not to mention keeping everything within your budget.

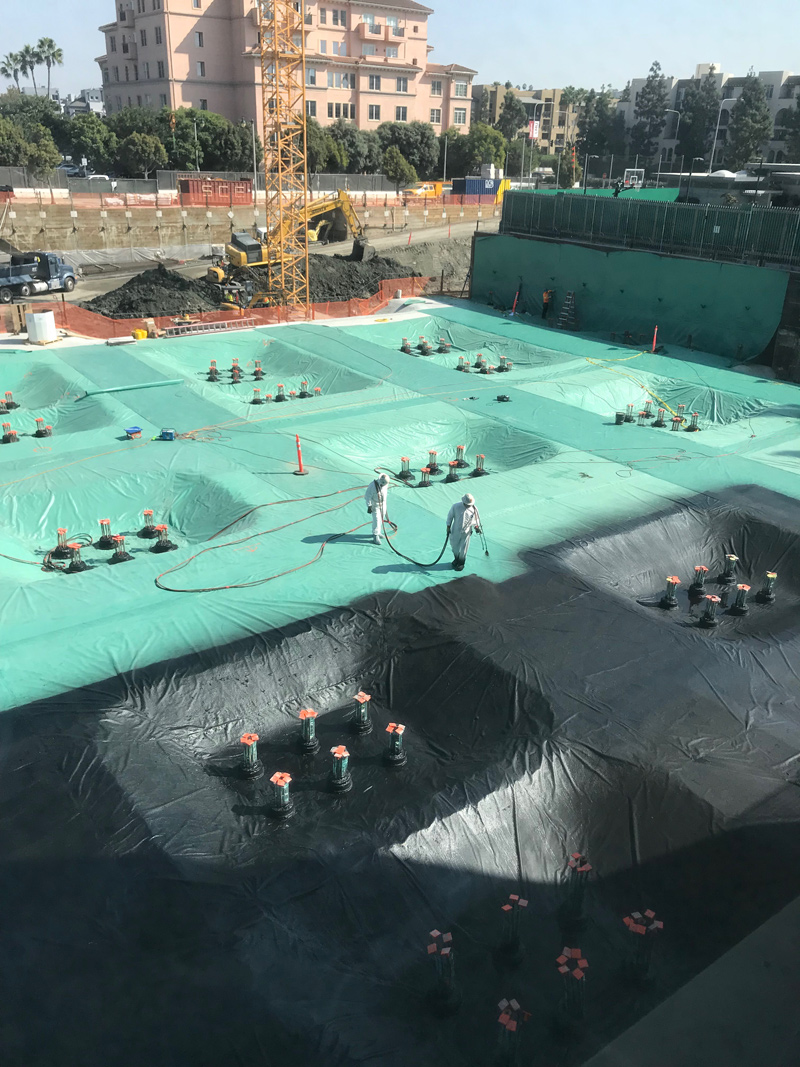

One of the most important aspects of planning a project is waterproofing. Water intrusion is a serious issue and can cause extensive, and thoroughly expensive, damage to a building and even harm the health of its occupants. If you don’t want to risk liability for this damage, it is vital to install sufficient waterproofing for any project.

Like any other aspect of planning a project, the costs of waterproofing must be determined. However, this is often very difficult, as there are many variables that can alter the cost of waterproofing. In this guide, we have listed the different cost considerations for choosing the right foundation waterproofing membrane for a new construction project, so that you can set an accurate budget.

What Is the Location?

The geographical location of a project is an important consideration. For example, prices of waterproofing materials will vary from state to state. The cost per square foot of waterproofing materials is likely to range significantly between more populous and industry-heavy states than it is in more rural areas. Labor costs are another consideration — local labor rates, worker availability and areas with more heavily unionized workers are likely to have higher costs.

Size and Scope of Project

The size and scope of a project play a large role in determining cost. Obviously, the larger the surface area that requires waterproofing means more materials will be needed and the overall cost is greater. However, cost per square foot does tend to decrease as surface area increases, as you will be purchasing materials in bulk.

When waterproofing the structure, there are a few factors to consider, such as whether the project is above-grade or below-grade. Above-grade projects are more open to the elements, whereas below-grade projects are more likely to be impacted by groundwater, complex foundations and other considerations. Below-grade applications are usually more expensive than above-grade applications. Other factors to consider include:

- Whether the material is pre-applied or post-applied

- Whether the material is applied vertically or horizontally

- The complexity of the foundation

- Whether any slope and drainage is required

In addition to the amount of material needed, these specifics will also affect the exact type of waterproofing membrane needed.

Type of Waterproofing

Choosing the right waterproofing membrane for the foundation is not necessarily a straightforward task, but is essential if you want to prevent water damage and make sure that a building remains secure and safe for many years and in all weather conditions.

There are many different types of materials used for waterproofing membranes. For example, PVC (polyvinyl chloride), HDPE (high-density polyethylene) or TPO (thermoplastic polyolefins) are typically used for sheet membranes, whereas different materials may be used for fluid-applied membranes or cementitious waterproofing.

Because the most suitable foundation materials vary by project, costs also vary. Plan carefully, and avoid assuming this cost will be the same or similar to past projects.

Labor Rates

As mentioned earlier, whether or not workers are unionized and specific unions can affect the costs of hiring labor and paying wages. However, there are also other factors to consider when working out the costs of hiring laborers for a project.

The number of laborers and the time needed to complete a project are also important considerations. Generally speaking, the more laborers hired, the less time used to complete a project, so hiring fewer laborers will not necessarily reduce costs. The level of specialized skill that a project requires of workers will also affect costs — the more qualified a worker, the higher their wage will typically be, and the better quality of work.

You should also factor in the possibility that the project may take more time than expected. As anybody in construction will know, there are plenty of things that can happen to cause delays. Another consideration includes the need to pay compensation in the event of accidents, although having the right insurance can protect against these costs.

Warranty Cost(s)

Warranty costs are an essential part of your budget for a project. If the material is damaged or leaks occur during the warranty period, a contractor may be liable to pay these costs to the client, depending on the specific terms of the warranty.

EPRO offers a variety of warranty options at a variety of prices to suit your budget and project requirements.

How Can EPRO Help You Plan a Cost-Effective Waterproof Commercial Foundation?

Planning a waterproofing solution that is as effective as possible while remaining within your budget is not usually a simple task. With so many different factors and variables to consider, this planning can often benefit from the help and guidance of experts.

EPRO has over thirty years of experience in waterproofing and containment systems and has installed fifty million square feet of waterproofing foundation. Our team has used its expert knowledge to help thousands of clients. With our huge variety of high-quality, durable waterproofing solutions, EPRO can help with any type of project.

Our team will evaluate the site and goals of your project, and present you with product options to suit a range of budgets. We will also identify potential problems and challenges of your specific project, and provide creative solutions.

We will install your chosen EPRO products, and the installation will be continuously monitored and verified to suit your requirements. One year after the completion of the project, we will return and evaluate the installation. In the event of any problems identified, we will fix them for you! Have any questions? Feel free to contact us at any time.