A case study presented earlier this year by Frank Schlaefli of Pinchin at Toronto's SMART Remediation conference demonstrates how careful planning, precise execution, and collaborative design can successfully mitigate soil vapor intrusion in contaminated industrial sites.

Soil vapor intrusion occurs when volatile or semi-volatile chemicals migrate from contaminated soil and groundwater into overlying buildings, creating involuntary exposure to toxic and potentially carcinogenic compounds through indoor air inhalation. The primary contaminants of concern include petroleum hydrocarbons such as BTEX compounds and petroleum hydrocarbon fractions F1 and F2, semi-volatile contaminants like select polycyclic aromatic hydrocarbons, and chlorinated volatile organic compounds including tetrachloroethylene (PCE) and trichloroethylene (TCE).

The challenge lies in the invisible nature of this contamination: Vapor intrusion occurs below ground level and enters buildings through foundation cracks, utility penetrations, and other pathways. Without proper mitigation, building occupants can be unknowingly exposed to harmful chemicals.

Pinchin presented a case study focusing on industrial legacy contamination. For over four decades, from 1967 to 2009, the property housed a water-based and solvent-based coating manufacturer . Operations ceased in 2009 and, in 2011, all above-grade structures were demolished, leaving behind a contaminated subsurface that required careful management before any redevelopment could proceed.

In 2018, a comprehensive Risk Assessment revealed the extent of contamination and established several risk management measures to mitigate potential human exposure. These measures included long-term groundwater monitoring, installation of a Sub-Slab Vapor Intrusion Mitigation System- Pinchin were retained to design this - for new construction, health and safety protocols, and various land use restrictions. The site received a Certificate of Property Use in 2018, paving the way for redevelopment into a large commercial and industrial facility for one of the country's largest e-commerce operations.

Engineering solutions and design coordination

An effective Sub-Slab Vapor Intrusion Mitigation System (SVMS) operates on the principle of creating a controlled pathway for contaminated vapors to escape before they can enter the building envelope. The system consists of three critical components working in harmony: a permeable venting layer beneath the building slab, a comprehensive collection system of perforated pipes, and a robust vapor barrier to prevent upward migration of contaminants.

The permeable venting layer, typically composed of carefully graded gravel, provides a pathway for vapor movement while maintaining structural integrity. Perforated pipes embedded within this layer create negative pressure zones that actively draw contaminated vapors away from the building foundation. An exhaust fan system maintains continuous suction, ensuring that vapors are efficiently removed and discharged safely above ground level.

Several potential solutions were evaluated during the design phase, including HVAC system upgrades, vapor barrier installations, floor sealing techniques, and both active and passive SVMS configurations. The team considered traditional pipe and gravel systems as well as more innovative void form-based ventilated floor designs before selecting the optimal approach for this specific site.

The selection of appropriate barrier membrane materials requires careful evaluation of chemical resistance properties, installation methods, thickness specifications, and permeance strength. The choice between seamless spray-applied membranes and welded or taped sheet systems can significantly impact both performance and installation complexity.

Implementation and QA/QC

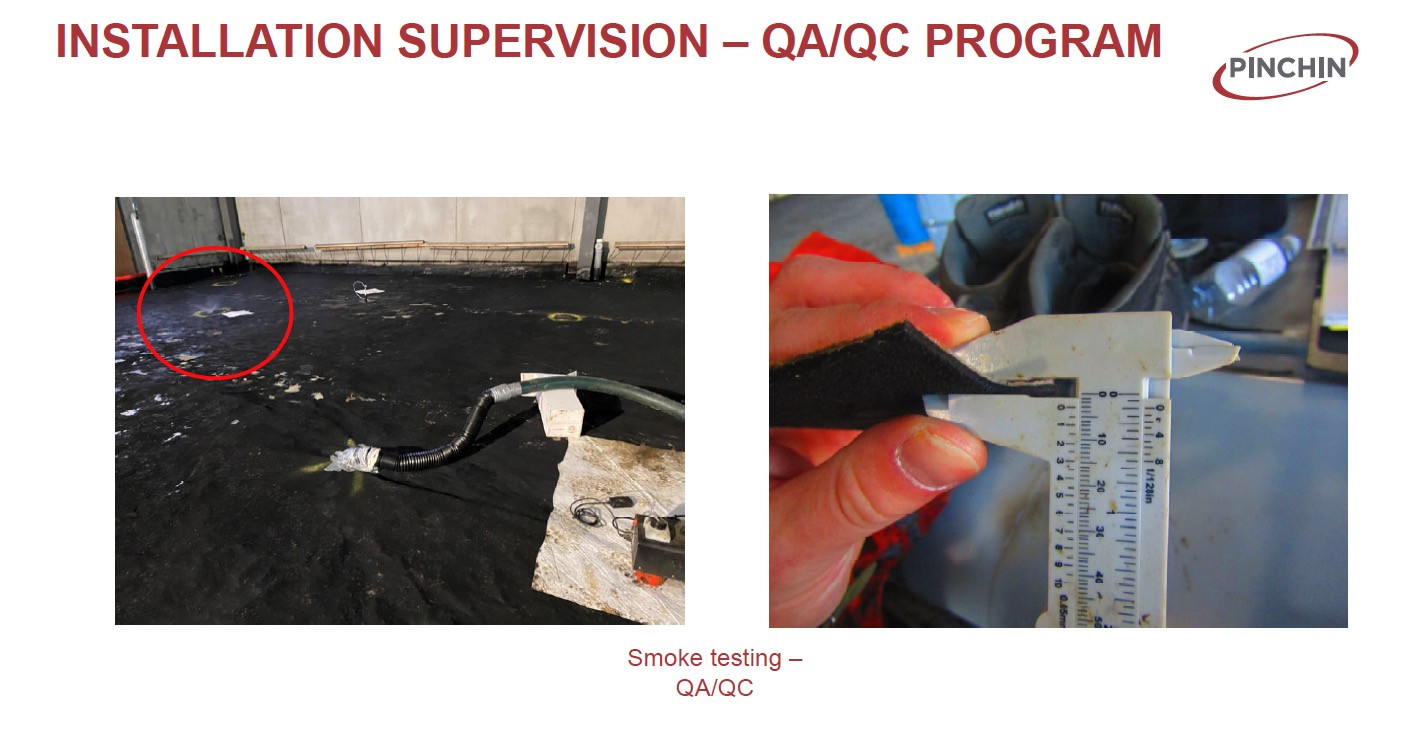

The installation phase demands meticulous quality assurance and quality control protocols to ensure system effectiveness. Every component requires careful inspection and approval, from the initial gravel layer installation through final concrete placement. The gravel must meet specific gradation and compaction requirements to provide optimal vapor flow characteristics while maintaining structural support for the overlying slab.

Perforated pipe installation requires precise elevation control and proper positioning within the gravel layer. Base fabric installation provides a separation layer that prevents concrete intrusion into the vapor collection system. The spray-on membrane application demands careful attention to coverage uniformity and adhesion quality.

However, one of the most critical quality control measures involves comprehensive smoke testing to verify system integrity and identify potential air leaks that could compromise performance. This testing occurs before final concrete placement, allowing for repairs and adjustments as needed.

Shield fabric installation provides additional protection for the membrane system during concrete operations. The final limestone screening layer and concrete work complete the system, creating a durable foundation that incorporates the vapor mitigation technology seamlessly into the building design.

Upon completion of installation, comprehensive performance testing validates system effectiveness and ensures compliance with design specifications. The testing protocol measures both airflow rates and pressure differentials throughout the system to confirm adequate vapor extraction capacity.

In this case study, performance testing demonstrated excellent results across multiple suction points. Flow rates ranged from 29 to 82 cubic feet per minute, with corresponding pressure measurements indicating effective coverage throughout the building footprint. Pressure monitoring at various test probes confirmed that the minimum pressure of negative 27.9 pascals was achieved.

Long Term Success and Environmental Impact

The project achieved all timeline objectives while delivering effective vapor intrusion mitigation. Post-construction monitoring through indoor air sampling and ongoing SVMS performance evaluation confirmed that the system performed as intended, successfully preventing vapor intrusion into the occupied building spaces.

The success of the mitigation system led to regulatory recognition of its effectiveness. The Ministry of Environment, Conservation and Parks reduced ongoing indoor air testing requirements based on the demonstrated performance, resulting in significant cost savings for the client while maintaining protection for building occupants.

Pinchin’s case study demonstrates that successful vapor intrusion mitigation requires more than just technical expertise in environmental engineering. It demands careful project planning, collaborative design coordination, rigorous quality control, and long-term performance monitoring. When these elements come together effectively, the result is a solution that protects human health while enabling productive reuse of formerly contaminated industrial properties.